14

2021

-

07

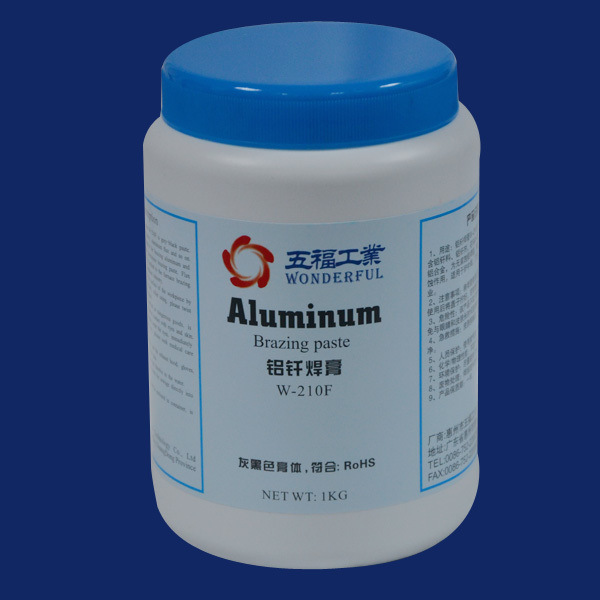

Aluminum welding flux is a flux used during aluminum welding.

Author:

Aluminum solderUsage: Used for welding aluminum wire, aluminum line, aluminum wire with copper; aluminum wire with iron, stainless steel.

Scope of application for aluminum solder: Suitable for the production of various high and low transformers, power distribution boxes, lighting distribution boxes, high-power voltage stabilizers, high-precision fully automatic voltage stabilizers, isolation type transformers of various models, motors, etc.

Method of use: First clean the welding surface thoroughly, then apply the aluminum solder to weld.

Aluminum solderPrecautions: 1. If there are residues on the surface after welding, they can be wiped clean with a wet wipe. 2. Welding temperature is 330+5 degrees. Performance: flame retardant, non-toxic and non-corrosive.

Industries using aluminum solder:

Aluminum solder is a paste-like viscous liquid. What is its main use? How much do you know about its applicable range? Let us introduce the general usage range of aluminum solder.

Aluminum solderIt is an essential soft soldering agent for lead-tin based soldering of aluminum, aluminum alloys, and welding between aluminum and copper, steel, copper alloys, etc. It can be used for welding aluminum enameled wire in the electronics industry and aluminum lamp holders in the bulb industry. Its main function is to remove the oxide film on the metal surface and increase the wettability of the solder on the metal surface, allowing the solder to bond with the metal substrate.

The wettability of the solder with aluminum and the bonding strength are related to the composition of the solder and the silicon and magnesium content in aluminum. Zinc can increase the wettability of the solder on the aluminum surface. However, it is difficult to solder with lead-tin solder for aluminum alloys with high magnesium and silicon content.

Aluminum solderClassification:

Different aluminum solders perform different functions during use, mainly depending on the type of aluminum solder. So how can we classify aluminum solders? Let's give a brief introduction to their classification.

There are many types of aluminum solders with various functions. They can be divided into five major categories based on the function and role of additives: crosslinking agents, process additives, etc.

Aluminum solderBy function, they can be divided into:

1. Optimize processing performance: lubricants, release agents, stabilizers, processing aids, thixotropic agents, etc.

2. Optimize mechanical properties: plasticizers, reinforcing fillers, toughening agents, impact modifiers.

3. Optimize optical properties: pigments, dyes, nucleating agents, fluorescent whitening agents.

Aluminum welding agent, gas flux, copper solder paste, aluminum brazing agent, brazing materials

Previous Page

Previous Page

10

2022-07

Aluminum welding flux is a flux used during aluminum welding.

30

2022-06

Aviation brazing materials are developing towards lower costs.

29

2022-06

The task control center plays an important role in handling soldering materials.

20

2022-06

Brazing process solutions, brazing equipment consulting, advanced brazing materials

15

2022-06

Selection of Gas Shielded Welding Wire - Flux-Cored Wire

08

2022-06

How to choose welding wire for gas shielded welding of steel?

28

2022-05

Types of gas shielded welding wires

Huizhou Wonderful Industrial Technology Co., Ltd.

Address: Yunshan West Road, Huicheng District, Huizhou City, Guangdong Province

Telephone:+86-752-2893501 +86-752-2200396

Website:www.cnwufu.com

E-mail:sales@cnwufu.com

![Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002 Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002](https://omo-oss-image.thefastimg.com/portal-saas/pg2024101223140586307/cms/image/8ecbaf85-b2f8-4cb1-9bc9-c03d9b218443.png)