28

2022

-

05

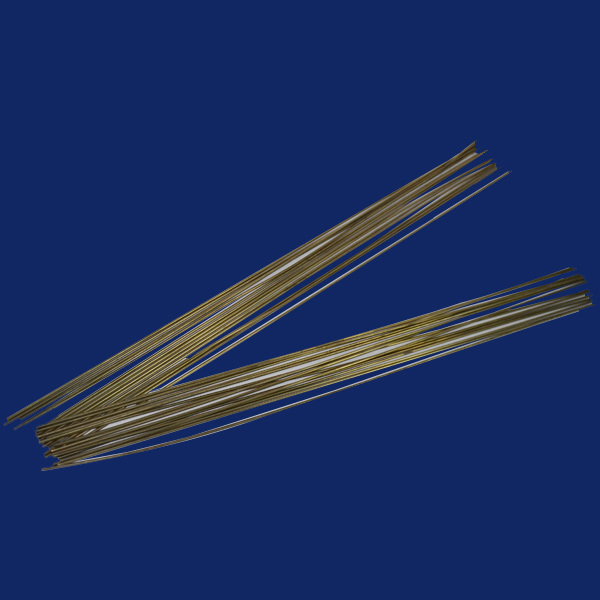

Types of gas shielded welding wires

Author:

Gas shielded welding wire can be said to be ubiquitous in daily life, but the average person may not notice it. It plays a significant role in our lives and work. It is found in the circuits of light bulbs, circuit boards of televisions, wires of rice cookers, and so on. Although we do not often come into contact with welding wire, non-professionals do not pay special attention to it, but it is indispensable in our lives. Next, let's specifically discuss the types of gas shielded welding wire.

Gas shielded welding wireFirst type: Flux-cored wire.

It is shaped as a round or special shape, formed by bending thin steel strips. Flux-cored wire is made by adding certain components to powder and then drawing it out. Alternatively, it can be made by filling a steel tube with a large amount of flux powder. The melting efficiency when welding with this wire is very high, and due to the good adaptability of the flux-cored wire to steel, the trial production cycle is shorter than that of other wires. The utilization rate, usage amount, and application range of flux-cored wire are continuously expanding.

Second type: Rolled wire.

Most choices for welding wire in the market are through rolled wire. The types of rolled wire mainly include: colored metal welding wire, stainless steel welding wire, carbon steel welding wire, alloy and structural steel welding wire, low-alloy structural steel welding wire, etc.

Gas shielded welding wireThird type: Cast welding wire.

Cast welding wire is mainly used for manual pile welding and has special properties such as resistance to oxidation, wear, and corrosion. Cobalt-chromium-tungsten welding wire is manufactured using liquid extrusion and continuous casting and is widely used in automatic TISCO gas shielded welding, improving the welding efficiency and quality of pile welds while greatly enhancing and improving working conditions.

Fourth type: Electric spark cold welding wire.

Typically, spark cooling welding wire is used for welding or overlaying at room temperature. Electric spark cold welding wire is mainly used for the repair of certain special performance parts that require high-temperature resistance. The temperature is usually controlled within 100 degrees Celsius, and some special requirements necessitate controlling the zero point at around 40 degrees Celsius. The reason for controlling the temperature of spark cooling wires within 100 degrees Celsius is that when the wires melt, some heat-resistant components may slightly melt. If the duration is too long, it will severely wash away the welding wire, causing the weld points to turn black and significantly affecting subsequent processing.

Gas shielded welding wireDivided into solid core wires and flux-cored wires, the usage of solid core wires still exceeds that of flux-cored wires; however, there are more varieties of flux-cored wires available including carbon steel, low-alloy high-strength steel, low-temperature steel, heat-resistant steel, stainless steel, etc., as well as various flux-cored wires suitable for overlaying. Depending on the different welding methods and shielding gases used, they can be classified into TIG wires, MIG wires, and MAG wires. With an increase in CO2 or O2 content in the shielding gas, the oxidizing nature of the arc atmosphere enhances. It requires that the welding wire contains sufficient deoxidizers such as silicon and manganese. Currently in our country, solid core wires are mainly used; however, flux-cored wires are rapidly being promoted for application with broad prospects.

Gas shielded welding wire, gas flux, brazing materials

10

2022-07

Aluminum welding flux is a flux used during aluminum welding.

30

2022-06

Aviation brazing materials are developing towards lower costs.

29

2022-06

The task control center plays an important role in handling soldering materials.

20

2022-06

Brazing process solutions, brazing equipment consulting, advanced brazing materials

15

2022-06

Selection of Gas Shielded Welding Wire - Flux-Cored Wire

08

2022-06

How to choose welding wire for gas shielded welding of steel?

28

2022-05

Types of gas shielded welding wires

Huizhou Wonderful Industrial Technology Co., Ltd.

Address: Yunshan West Road, Huicheng District, Huizhou City, Guangdong Province

Telephone:+86-752-2893501 +86-752-2200396

Mobile Phone: +86-13068287611-Mr. Chen

Website:www.cnwufu.com

E-mail:sales@cnwufu.com

![Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002 Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002](https://omo-oss-image.thefastimg.com/portal-saas/pg2024101223140586307/cms/image/8ecbaf85-b2f8-4cb1-9bc9-c03d9b218443.png)