24

2021

-

10

What methods are there for using flux on workpieces?

Author:

Generally, we require the flux to be applied to the brazing area of the workpiece before brazing. This can reduce the possibility of flux contamination or falling off. According toFluxdifferent forms, there are many methods to apply flux to the workpiece in industrial applications. Below is a brief introduction to commonly used methods.

1. Thermal Electrode Dipping

During manual flame brazing, slightly preheat the end of the electrode with a flame, insert the heated end into powdered flux (such as okna dryFlux, okna 737, and fb102), then pull it out, allowing the powdered flux to adhere to the hot electrode. After preheating the part, apply the adhered flux to the brazing area of the workpiece.

2. Rushing

Generally suitable for paste fluxes (such as okna flux, okna flux B-1). Before brazing, brush a thin layer of flux on the mating surface of the workpiece, then assemble the joint. During heating, the flux is heated and melted to take effect. Flux can be added manually or preset on formed parts at the joint.

3. Spot Application

Typically, brazing flux is applied to the workpiece using structures like syringes or welding guns through manual squeezing or compressed air. The flux used should be spot adhesive type (such as okna disposable flux). This method is very suitable for automation, setting pressure and adhesion time, and precisely controlling the amount of flux at each weld point.

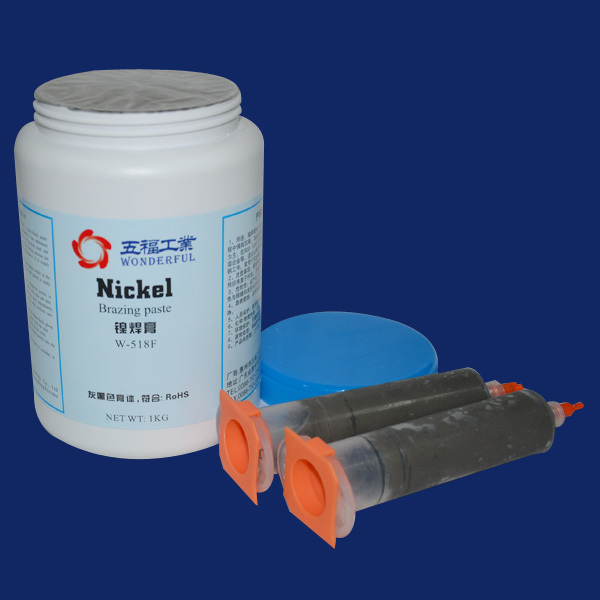

4. Adding Flux - Solder Combination Form

Common combination forms include solder paste, core materials, and skins. In combination forms, the ratio of solder andFluxis preset, and almost all solder and flux are added in the same ratio. During brazing, the combination form is directly added to the workpiece without separately adding flux. When heated, the flux first melts and takes effect, then the solder in the component melts and fills the joint to complete brazing.

5. Dipping

This method involves directly immersing all or part of the workpiece in flux, allowing it to adhere to the surface of the workpiece. It is generally suitable for low concentration paste flux or mixed powder flux slurries. When adding flux using this method, the surface of the workpiece should be clean, and regular checks on changes in concentration of the flux tank should be conducted to avoid contamination.

6. Spraying/Spraying

It is usually suitable for paste or slurry-type fluxes. The flux is sprayed onto the surface of the workpiece using an air knife. By adjusting the angle of the air knife, you can control the amount of flux sprayed onto the surface of the workpiece. The attached flux from this method is uniform and has a good effect on large area brazing. However, this method has a low single-use rate for flux, and recovered flux may be contaminated.

Flux, commonly referred to as brazing agent or soldering agent, plays the following roles throughout the brazing process:

1. Remove, destroy or dissolve oxide films on the surface of base metals through physical and chemical actions;

2. Promote wetting and diffusion of solder on base material surfaces;

3. Isolate air to prevent re-oxidation of joints during brazing;

To ensure quality in brazed joints, most brazing situations require using a flux; however, brazing conditions include vacuum furnaces, reducing atmosphere protective furnaces, and copper cup series solder brazing.

Gas shielded welding wire, aluminum welding flux, brazing agent, aluminum brazing flux, brazing materials

Previous Page

10

2022-07

Aluminum welding flux is a flux used during aluminum welding.

30

2022-06

Aviation brazing materials are developing towards lower costs.

29

2022-06

The task control center plays an important role in handling soldering materials.

20

2022-06

Brazing process solutions, brazing equipment consulting, advanced brazing materials

15

2022-06

Selection of Gas Shielded Welding Wire - Flux-Cored Wire

08

2022-06

How to choose welding wire for gas shielded welding of steel?

28

2022-05

Types of gas shielded welding wires

Huizhou Wonderful Industrial Technology Co., Ltd.

Address: Yunshan West Road, Huicheng District, Huizhou City, Guangdong Province

Telephone:+86-752-2893501 +86-752-2200396

Website:www.cnwufu.com

E-mail:sales@cnwufu.com

![Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002 Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002](https://omo-oss-image.thefastimg.com/portal-saas/pg2024101223140586307/cms/image/8ecbaf85-b2f8-4cb1-9bc9-c03d9b218443.png)