21

2021

-

10

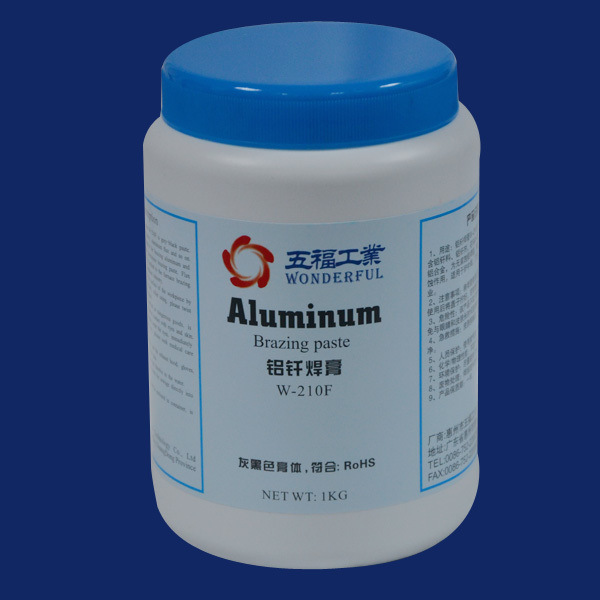

An introduction to a low corrosive, cost-effective aluminum brazing filler metal.

Author:

Aluminum and aluminum alloys have excellent physical and chemical properties, good processability, surface treatment characteristics, and corrosion resistance, and are widely used in aerospace, automotive, machinery manufacturing, chemical industry, and other fields. Brazing, as an important material connection technology, has the advantages of low thermal stress and minimal post-weld deformation, making it suitable for one-time connection forming of multiple welds and parts. The processing and manufacturing of aluminum and aluminum alloy parts have always been a common practice. However, the weldability of aluminum and its alloys is much poorer than that of steel, copper, and copper alloys because the surface of aluminum and its alloys easily forms a very dense oxide film. In flame brazing and furnace brazing, special aluminum brazing flux is required to remove the oxide film from the surface of aluminum and aluminum alloys.aluminum brazing flux, which effectively removes the oxide film. Among them, AlF3-KF flux has the advantages of good oxide film removal effect, non-hygroscopicity, non-corrosiveness, and no need for cleaning after welding. However, AlF3-KF solder has a significant drawback: its melting point is too high. Therefore, it is necessary to study a new type of aluminum brazing flux with a low melting point, non-corrosiveness, lower cost, suitable for flame brazing.

To solve the current problem of AlF3-KF flux having too high a melting point and being unsuitable for flame brazing, technicians have provided a medium-temperature non-corrosivealuminum brazing fluxand its preparation method. To achieve the above objectives, it is implemented using the following technical scheme: an aluminum brazing flux composed of one or two of aluminum trifluoride, potassium fluoride, zinc dichloride, and lithium fluoride or sodium fluoride. The specific components include: 35.45% aluminum trifluoride, 32.42% potassium fluoride, 5% zinc dichloride, etc.

The preparation steps for this medium-temperature non-corrosive aluminum brazing flux are as follows: First, analyze pure reagents such as aluminum trifluoride, potassium fluoride, zinc dichloride under high temperature to dehydrate them respectively; then place them in a vacuum drying oven and dry at high temperatures between 110 to 150 degrees Celsius for 12-15 hours. After drying, grind the reagents into powder. Next, according to the formula of the flux, weigh the reagent powder into a crucible, add deionized water, and stir with a glass rod to make a mixture. Then place the crucible containing the mixed solution into a crucible furnace at 150 degrees Celsius and heat until the mixed solution boils. During this period, maintain the temperature for 5-10 minutes until the mixed solution evaporates. Finally, remove the crucible and place it in a vacuum drying oven under conditions of -0.05 to -0.1 MPa vacuum for 16-24 hours; then take out the completely dried material from the crucible and grind it into powder to obtain the finished brazing material.

Thealuminum brazing fluxadvantages are: 1. By adding a certain amount of lithium fluoride and sodium fluoride to lower the melting point of the flux; this solder can not only braze pure aluminum and 3003 aluminum alloy but also some series 5 and series 6 alloys. 2. The Zn2+ cations in zinc dichloride added to the solder can react with the aluminum base material to enhance the activity of the solder and improve its ability to remove oxide films from aluminum alloy surfaces, thereby enhancing its wettability and joint filling capacity. 3. During flame brazing with this flux, by optimizing its structure, it avoids hydrolysis failure of flux F4 and improves its flame adaptability. 4. The preparation method of this aluminum brazing flux is simple; the finished solder does not absorb moisture and can be stored in the atmosphere for long periods without losing effectiveness; after brazing with this solder, residue does not absorb moisture and is non-corrosive to joints. 5. The preparation process is simple with low raw material costs suitable for large-scale production and application.

Yin qian han, lu wan ji, qi ti zhu han ji, tong wan gao, lu qian ji, yin wan liao, qian han cai liao

10

2022-07

Aluminum welding flux is a flux used during aluminum welding.

30

2022-06

Aviation brazing materials are developing towards lower costs.

29

2022-06

The task control center plays an important role in handling soldering materials.

20

2022-06

Brazing process solutions, brazing equipment consulting, advanced brazing materials

15

2022-06

Selection of Gas Shielded Welding Wire - Flux-Cored Wire

08

2022-06

How to choose welding wire for gas shielded welding of steel?

28

2022-05

Types of gas shielded welding wires

Huizhou Wonderful Industrial Technology Co., Ltd.

Address: Yunshan West Road, Huicheng District, Huizhou City, Guangdong Province

Telephone:+86-752-2893501 +86-752-2200396

Mobile Phone: +86-13068287611-Mr. Chen

Website:www.cnwufu.com

E-mail:sales@cnwufu.com

![Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002 Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002](https://omo-oss-image.thefastimg.com/portal-saas/pg2024101223140586307/cms/image/8ecbaf85-b2f8-4cb1-9bc9-c03d9b218443.png)