07

2021

-

10

Introduction to a method for making copper solder paste for brazing.

Author:

With the development of science and technology, the rapid advancement of modern electronics industry,Copper solder pasteis an important production link in the soldering of electronic products. However, traditional copper solder paste contains a large amount of lead, producing a lot of smoke and dust, and is gradually being replaced. The trend is to use low-silver solder alloys for lead-free electronic assembly to improve cost-effectiveness. Currently, technicians have prepared copper solder paste based on sac305 in the existing market, but its disadvantage is high cost. Therefore, we urgently need to reduce the Ag content in the solder alloy to improve the cost-effectiveness of the assembly process. At present, copper solder paste has become a key material for microelectronic chip mounting in the computer, radar, and audio equipment industries. As electronic devices develop towards miniaturization, lightweight design, and high reliability, the size of solder joints is getting smaller, but their mechanical and electrical loads are increasing. The issue of cleaning residues after soldering has attracted the attention of many experts worldwide.

Technical elements: Technicians provided a solderingCopper solder paste, reducing or even eliminating the consumption of corrosive fluxes. This copper solder paste has excellent spreadability and soldering performance. The technical solution for this copper solder paste is achieved as follows: The soldering copper solder paste is composed of 60-70% copper-based powder solder, 2-6% flux, 10-30% composite solvent, 0.5-1% corrosion inhibitor, 1-3% thixotropic agent, and 4-8% activator by weight percentage, with zinc fluoride as the flux. In addition, the copper-based solder powder is atomized spherical powder with a particle size of 40-100 microns. The solder alloy system is selected from at least one of pure copper, cu-5p-9ni-5sn, cu-25ni-2.5si-0.2b, and cu-20ag-36zn-1ni. The corrosion inhibitor is selected from at least one of benzotriazole, vitamin C, triethylamine, and l-ascorbic acid palmitate. The thixotropic agent is hydrogenated castor oil, modified castor oil, glycerin or stearic acid; the activator is diynediol or silicone oil. A preparation method for a soldering copper solder paste includes the following steps: 1. Prepare copper-based powder solder; 2. First place the composite solvent and flux into a container with a dispersion device according to the formulation amount, heat and continuously stir until the material completely dissolves; then add the activator all at once while continuing to heat and stir until all materials completely dissolve into a clear, thin, viscous liquid; then add copper-based metal powder solder and stir evenly before discharging.

In summary, the beneficial effects of the above preparation method are: by screening the solder and adding a small amount of zinc fluoride, stannous fluoride or cuprous fluoride can achieve the same effect as fluoroborate; by selecting composite solvents from screened solvents, especially those composed of tetrahydroxy alcohols, triglycol and dibutyl ether can make copper solder paste have better wettability and fuller appearance of solder joints with a spreadability rate exceeding 95%, far higher than traditional alcohol ether composite solvents.Copper solder paste制备方法的有益效果是:通过筛选焊料并加入少量,氟化锌、氟化亚锡或氟化铜可以达到与氟硼酸盐相同的效果,通过筛选溶剂选择复合溶剂,尤其是由四氢糖醇、三甘醇和二甘醇丁醚组成的溶剂,使铜焊膏具有更好的润湿性和更饱满的焊点外观,铺展率达95%以上,远高于传统醇醚复合溶剂。

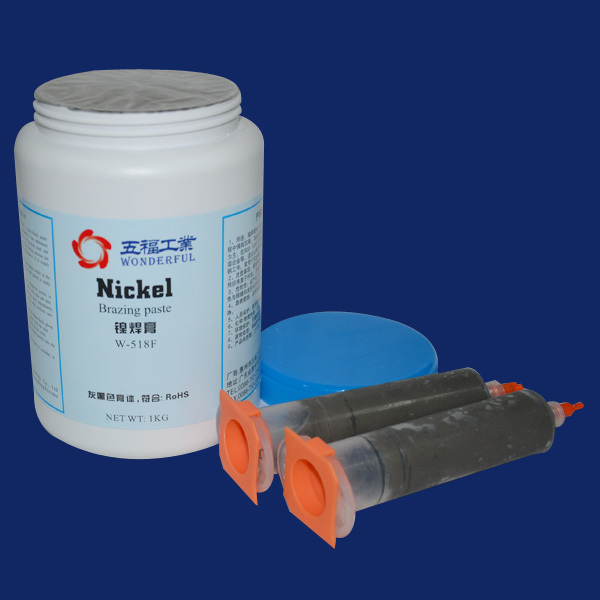

Solder, silver brazing, aluminum flux, gas flux, copper solder paste, silver solder

10

2022-07

Aluminum welding flux is a flux used during aluminum welding.

30

2022-06

Aviation brazing materials are developing towards lower costs.

29

2022-06

The task control center plays an important role in handling soldering materials.

20

2022-06

Brazing process solutions, brazing equipment consulting, advanced brazing materials

15

2022-06

Selection of Gas Shielded Welding Wire - Flux-Cored Wire

08

2022-06

How to choose welding wire for gas shielded welding of steel?

28

2022-05

Types of gas shielded welding wires

Huizhou Wonderful Industrial Technology Co., Ltd.

Address: Yunshan West Road, Huicheng District, Huizhou City, Guangdong Province

Telephone:+86-752-2893501 +86-752-2200396

Mobile Phone: +86-13068287611-Mr. Chen

Website:www.cnwufu.com

E-mail:sales@cnwufu.com

![Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002 Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002](https://omo-oss-image.thefastimg.com/portal-saas/pg2024101223140586307/cms/image/8ecbaf85-b2f8-4cb1-9bc9-c03d9b218443.png)