01

2021

-

10

A high-efficiency dust-free thin film coating agent device

Author:

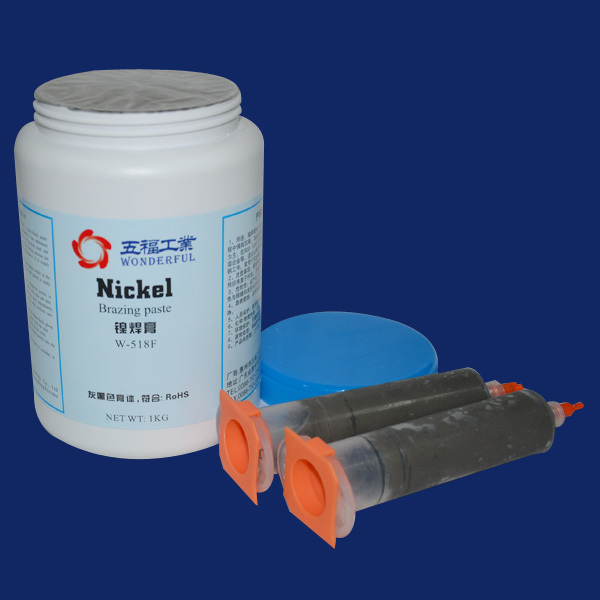

Flux refers to the soldering agent used in brazing.FluxIts function is to remove oxides from the surfaces of the base material and filler metal, protect the base material and filler metal, reduce oxidation during the heating process, improve the wettability of the filler metal to the base material, and effectively dissolve or destroy the oxide film on the surfaces of the workpiece and filler metal. Among them, the application of thin sheet flux coating devices is relatively common. Nowadays, there are various types of such equipment on the market that can basically meet people's basic needs, but many problems still trouble people, such as: traditional equipment requires long manual operation, which seriously affects workers' health when using the equipment; dust can fall in during use, greatly affecting the purity during operation. Natural drying is required during use, resulting in a long overall cleaning time, which brings great difficulties to users.

To solve the above-mentioned background technologyFluxIn order to address issues such as low efficiency, safety concerns, and poor coating effects of coating devices, technicians have provided a dust-free thin sheet coating flux device. To achieve this purpose, it adopts the following technical scheme: a thin sheet coating flux device includes a shell, support frame, supply pipe, control panel, and positioning groove. The control panel is installed at the center of the top of the shell, and the positioning groove is fixed at the center of the top of the control panel; one end of the shell surface is hinged with a door body, and a handle is welded on the surface of the door body; a support frame is welded on top of the shell, with an air supply pipe installed on one side of its surface. One end of the supply pipe extends outside the support frame, an electromagnetic valve is fixed on the surface of the supply pipe, a nozzle is installed at one end of the supply pipe, and a control panel is fixed on one side of the surface of the support frame. The output end of a microcontroller in the control panel is electrically connected to the input end of the electromagnetic valve. A feed nut is fitted on the surface of a screw rod, with rectangular blocks welded on both sides of it. Sliding frames are installed on both sides of a horizontal box surface, with one end of a rectangular block welded with a hollow block. A cylinder is installed at the bottom end of this hollow block, and its input end is electrically connected to the output end of a microcontroller in the control panel.

Among them, support legs are welded at the corners of the bottom of the outer shell. Inside the shell, heating plates are welded at equal intervals. A dust collection box is installed on one side of the support frame surface, with a fan fixed inside it; one side of this fan has a purification core installed. The purification core has a resin cotton filter layer inside it, with an activated carbon adsorption plate fixed at one end of this resin cotton filter layer. A partition is fixed at the center top of each heating plate.

Compared with existing technology, this thin sheet coatingFluxdevice has the following beneficial effects: 1. By optimizing structure and production processes, not only has it improved device purity but also effectively increased production efficiency; 2. By optimizing structure, it has achieved dust-free functionality for equipment and improved purity during use; 3. By optimizing settings with a hinged door at one end of the shell surface and evenly spaced heating plates welded inside it, it has realized automatic drying functionality for equipment, thus enhancing production efficiency; 4. Through optimized design with a cylinder at the bottom end of a hollow block and a brush roller hinged at an end away from this cylinder, it has reduced manual operation steps and avoided potential health hazards to workers during device use.

Gas shielded welding wire, aluminum welding flux, brazing agent, aluminum brazing flux, brazing materials

10

2022-07

Aluminum welding flux is a flux used during aluminum welding.

30

2022-06

Aviation brazing materials are developing towards lower costs.

29

2022-06

The task control center plays an important role in handling soldering materials.

20

2022-06

Brazing process solutions, brazing equipment consulting, advanced brazing materials

15

2022-06

Selection of Gas Shielded Welding Wire - Flux-Cored Wire

08

2022-06

How to choose welding wire for gas shielded welding of steel?

28

2022-05

Types of gas shielded welding wires

Huizhou Wonderful Industrial Technology Co., Ltd.

Address: Yunshan West Road, Huicheng District, Huizhou City, Guangdong Province

Telephone:+86-752-2893501 +86-752-2200396

Mobile Phone: +86-13068287611-Mr. Chen

Website:www.cnwufu.com

E-mail:sales@cnwufu.com

![Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002 Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002](https://omo-oss-image.thefastimg.com/portal-saas/pg2024101223140586307/cms/image/8ecbaf85-b2f8-4cb1-9bc9-c03d9b218443.png)