02

2021

-

06

Using gas flux can improve production efficiency and reduce costs.

Author:

Gas fluxIt is a flux added to the flame for brazing. The gas flow is introduced into a dedicated device called a 'flow generator', which enters the gas generator (acetylene, liquefied gas, propane, etc.) in the form of steam and flow, then reaches the torch through pipes, producing a bright green flame. By covering the brazing parts, the flame can improve the wettability and fluidity of the solder, reduce the occurrence of pinholes, and enhance the strength of the weld. There is no oxidation on the metal surface in the brazing area, and acid pickling is not required after welding. Gas flux can improve production efficiency and reduce costs.

Gas fluxIt is a modern, high-speed, economical brazing method that adds flux to the flame for brazing copper and silver. The gas flux is a highly volatile liquid compound that is non-corrosive and fluorine-free. The gas flux is introduced into the gas line of the gas source, emitting a bright green light during welding. The flux is sprayed from the welding gun with the flame, automatically and evenly delivered to the welding area, forming a protective film to prevent oxidation of the weld metal surface and lubricate the welding area, thereby improving welding quality and preventing harmful gas generation.

UsageGas fluxDuring brazing, low-silver lead materials such as material 204 can be used to reduce enterprise costs. After welding, the brazing research area develops clean, bright surfaces with minimal residues. Due to the addition of gas flux, an 'atomized' state is formed in the flame, meaning uniform addition of flux significantly increases control over weld quality and welding technology levels, reducing the likelihood of leaks affecting welds and ensuring the formation of economically high-quality welds.

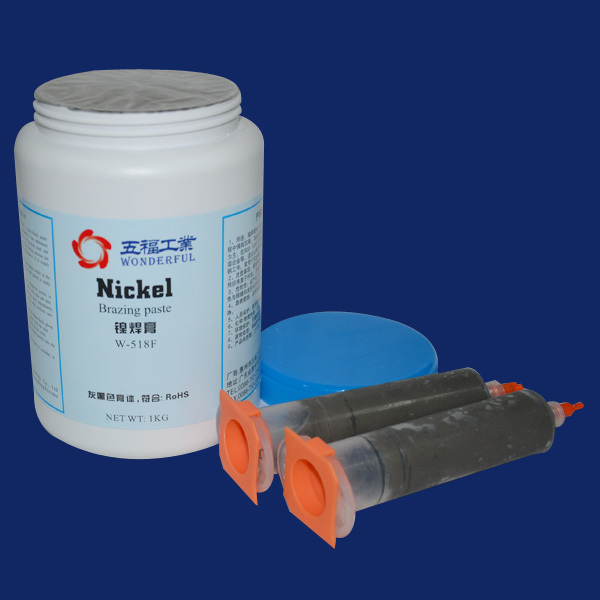

Huizhou Wufu Industrial Technology Co., Ltd. is a high-tech enterprise engaged in R&D, manufacturing, and sales of environmentally friendly brazing series products. It is a member unit of the Chinese Welding Society and closely collaborates with many universities and research institutions across the country, possessing a strong research team. Products include silver solder, brazing materials, aluminum solder, brazing materials, copper solder paste, silver solder, solder.Gas fluxCopper fluxes, etc., Wufu has the capability to provide customers with overall design, production process planning, and solutions to specific problems. With a focus on customers and technology, we strive to provide high-quality products and services that meet customer needs and expectations. Wufu has the capability to provide customers with overall design, production process planning, and solutions to specific problems. We welcome your inquiries.

Gas shielded welding wire, silver brazing, aluminum soldering flux, gas flux, brazing materials

Previous Page

Previous Page

10

2022-07

Aluminum welding flux is a flux used during aluminum welding.

30

2022-06

Aviation brazing materials are developing towards lower costs.

29

2022-06

The task control center plays an important role in handling soldering materials.

20

2022-06

Brazing process solutions, brazing equipment consulting, advanced brazing materials

15

2022-06

Selection of Gas Shielded Welding Wire - Flux-Cored Wire

08

2022-06

How to choose welding wire for gas shielded welding of steel?

28

2022-05

Types of gas shielded welding wires

Huizhou Wonderful Industrial Technology Co., Ltd.

Address: Yunshan West Road, Huicheng District, Huizhou City, Guangdong Province

Telephone:+86-752-2893501 +86-752-2200396

Website:www.cnwufu.com

E-mail:sales@cnwufu.com

![Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002 Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002](https://omo-oss-image.thefastimg.com/portal-saas/pg2024101223140586307/cms/image/8ecbaf85-b2f8-4cb1-9bc9-c03d9b218443.png)