18

2021

-

04

Introduction to the composition and uses of different silver solder.

Author:

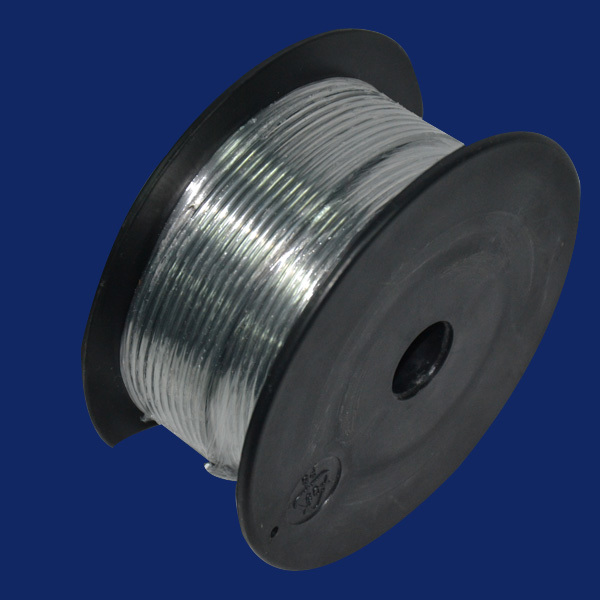

BCu80PAg(HL204)(TS-15P) silver welding rods, silver welding wiresSilver solderMain chemical components: Ag: 15±1, P: 5±0.2, Cu: balance. Performance: Soldering temperature 704-816℃, good strength, plasticity, and conductivity of the solder joints. Application: Suitable for soldering copper, copper alloys, silver alloys, tungsten, molybdenum, and other metals.

BAg18CuZnSn(TS-18P) silver welding rods, silver welding wires, silver solder. Main chemical components: Ag: 18±1, Cu: 44±1, Sn: 20±2, Zn: balance. Performance: Soldering temperature 810-900℃, low silver content, low price, high soldering temperature, good soldering process performance, high weld strength. Application: Suitable for soldering copper and copper alloys.

BAg25CuZnSn(TS-25P) silver welding rods, silver welding wiresSilver solderMain chemical components: Ag: 25±1, Cu: 36±1, Sn: 5, Zn: balance. Performance: Soldering temperature 760-810℃, good fluidity, smoother solder joints. Application: Suitable for soldering copper, copper alloys, silver-nickel alloys, steel and stainless steel. Can replace HL303 silver welding rods containing cadmium or tin.

BAg60CuSn main chemical components: Ag: 60±1, Sn: 9.5±1, Cu: balance. Performance: Soldering temperature 720-840℃, low melting point, good conductivity. Application: Suitable for final soldering of vacuum devices with good weld cleanliness.

BAg35CuZnCd(HL314) silver welding rods, silver welding wires, silver solder. Main chemical components: Ag: 35±1, Cu: 27±2, Cd: 18±1, Zn: balance. Performance: Soldering temperature 700-845℃; can fill larger or uneven welds but requires fast heating to prevent segregation. Application: Suitable for soldering copper, copper alloys, steel and stainless steel.

BAg45CuZnCd silver welding rods, silver welding wires, silver solder. Main chemical components: Ag: 45±1, Cu: 15±1, Cd: 24±1, Zn: balance. Performance: Soldering temperature 635-760℃. Application: Suitable for materials requiring lower soldering temperatures.Silver solderBAg50CuZnCd(HL313) silver welding rods, silver welding wires

Main chemical components: Ag: 50±1, Cu: 15.5±1, Cd: 18±1, Zn: balance. Performance: Soldering temperature 635-780℃; low melting point and high joint strength. Application: Suitable for soldering copper, copper alloys, steel and stainless steel.

Solder, gas shielded welding wire, silver brazing, silver solder

10

2022-07

Aluminum welding flux is a flux used during aluminum welding.

30

2022-06

Aviation brazing materials are developing towards lower costs.

29

2022-06

The task control center plays an important role in handling soldering materials.

20

2022-06

Brazing process solutions, brazing equipment consulting, advanced brazing materials

15

2022-06

Selection of Gas Shielded Welding Wire - Flux-Cored Wire

08

2022-06

How to choose welding wire for gas shielded welding of steel?

28

2022-05

Types of gas shielded welding wires

Huizhou Wonderful Industrial Technology Co., Ltd.

Address: Yunshan West Road, Huicheng District, Huizhou City, Guangdong Province

Telephone:+86-752-2893501 +86-752-2200396

Website:www.cnwufu.com

E-mail:sales@cnwufu.com

![Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002 Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002](https://omo-oss-image.thefastimg.com/portal-saas/pg2024101223140586307/cms/image/8ecbaf85-b2f8-4cb1-9bc9-c03d9b218443.png)