09

2020

-

11

Introduction to High-Frequency Brazing Process

Author:

Stainless steel contains chromium, which is particularly sensitive to oxygen and easily forms chromium oxide. When the surface of the workpiece presents this state, the wettability of the solder is poor, leading to potential gas leakage. To achieve high-quality brazed joints, it is essential to effectively remove chromium oxides. The following introduceshigh-frequency brazingthe process principle.

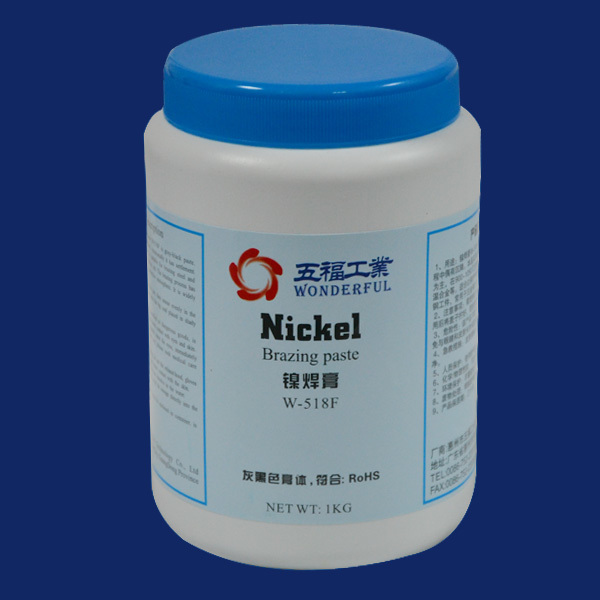

Under prolonged heating at 450-700°C, electronic tube stainless steel components exhibit the following conditions during the manufacturing process of vacuum devices: 1Cr18Ni9 stainless steel precipitates chromium carbide at austenite grain boundaries, resulting in chromium depletion at these temperatures. High-frequency brazing addresses this issue by nickel plating the stainless steel surface, a common practice in past production.

Ordinary nickel plating on stainless steel takes 2-4 hours to complete, with a coating thickness of over 20μm. If the welding method is improperly used, it can lead to weld seam peeling. The impact nickel plating process has improved the coating thickness to about 2μm, enhancing its wear resistance. Tests on pipe manufacturing showed good solder flow and strong weld seams without cracks. In practical work, issues such as poor solder loss and gas leakage may occur; for this, remedial measures like a brief electric brush plating of over ten seconds can be taken. Multiple practices have proven this method to be suitable for high-frequency brazing of vacuum microwave traveling wave tubes. The impact nickel plating high-frequency brazing process is simple, easy to operate, uses hydrogen gas quickly and cost-effectively, and is conducive to mass production of products.

Stainless steelhigh-frequency brazingthe main processes include brazing temperature, holding time, joint gap, and solder flow to obtain high-quality brazed joints. The welding temperature is a key factor determining weld seam quality; it must ensure that the welding material is fully liquefied and flows maximally while keeping the temperature within the weld seam from being too high. The melting temperature of the welding material varies based on its chemical composition and should generally be above the liquidus line of the solder to ensure that the solder melts at high-frequency brazing temperatures, achieving optimal fluidity and wettability.

Welding time determines the dispersion of various elements in the solder relative to the base metal and is an important factor affecting the performance of brazed joints. If the brazing time is too short, insufficient flow of solder in the seam will directly impact welding quality. Once high-frequency brazing time reaches a certain value, the dissolution of solder into the base metal becomes saturated; extending holding time further will not change the thickness of base metal dissolution but may cause some elements to volatilize, affecting weld seam quality. Therefore, holding time should be minimized while ensuring sufficient dispersion of solder and wetting of the base metal being welded.

The welding gap determines the flowability of the solder and significantly affects the mechanical properties of the welded joint; this aligns with the interaction characteristics between solder and base materials. For example, when solder is in a molten state and adequately wets base metal materials but does not interact strongly with them, a smaller joint gap can be considered. Conversely, when there is strong interaction between solder and base materials during high-frequency brazing—due to increasing melting points as base metal integrates into solder—if welding temperature remains unchanged, flowability will decrease; thus, in such cases, an appropriate increase in joint gap is necessary. For silver brazing, joint dimensions should be between 0.05-0.08 millimeters. When using protective gas for copper brazing, joint dimensions must not exceed 0.012 millimeters. To achieve high-quality and reliable brazed joints, controlling gaps is essential.

The high-frequency brazing process does not use flux or require expensive and complex equipment; only ordinaryhigh-frequency brazingequipment is needed. This avoids contamination from flux on devices while shortening equipment usage cycles, maintaining the original performance of stainless steel pipe shells while keeping parts clean throughout the process.

The significant advantage of using high-frequency brazing on stainless steel is its rapid local heating speed; chromium oxides have not yet decomposed when solder disperses and cools quickly, ensuring strong weld seams.

High-frequency brazing, copper solder paste, copper solder paste manufacturer

Previous Page

Next Page

Previous Page

Next Page

10

2022-07

Aluminum welding flux is a flux used during aluminum welding.

30

2022-06

Aviation brazing materials are developing towards lower costs.

29

2022-06

The task control center plays an important role in handling soldering materials.

20

2022-06

Brazing process solutions, brazing equipment consulting, advanced brazing materials

15

2022-06

Selection of Gas Shielded Welding Wire - Flux-Cored Wire

08

2022-06

How to choose welding wire for gas shielded welding of steel?

28

2022-05

Types of gas shielded welding wires

Huizhou Wonderful Industrial Technology Co., Ltd.

Address: Yunshan West Road, Huicheng District, Huizhou City, Guangdong Province

Telephone:+86-752-2893501 +86-752-2200396

Website:www.cnwufu.com

E-mail:sales@cnwufu.com

![Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002 Notice on the Spring Festival Holiday in 2024 Huizhou Wufu Industrial Document [2024]002](https://omo-oss-image.thefastimg.com/portal-saas/pg2024101223140586307/cms/image/8ecbaf85-b2f8-4cb1-9bc9-c03d9b218443.png)